Electropolishing machine

Thank you for visiting NSC Engineering Division’s homepage.

If you are looking for an electropolishing machine, please contact NSC. We provide a wide variety of automatic machines from large-sized machines for mass production to small-sized machines for experiment.

From experimental machines, machine prototypes to mass production machines, NSC provides machines in different scales

|

Electropolishing process can be automatized if all the workpieces come with a fixed shape.

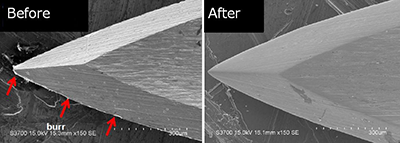

As an example for automatized machine, we have records in developing the best process condition and in supplying to our end users electropolishing machines which automatically performs deburring for injection needles.

|

Specification examples of our electropolishing machine

Electropolishing machine for needle

|

Item

|

Overview

|

|---|---|

| Use |

Deburring

|

| Material of work |

Austenitic stainless steel

|

| Size of work |

(As an example) Outer diameter: 0.69 mm, Length: 60 mm

|

| Chemicals mainly used |

Phosphoric acid electrolyte

|

| Current value |

~1000A

|

| Main equipment |

|

| Main functions |

|

| option |

|

barrel electrolytic polishing machine

|

Item

|

Overview

|

|---|---|

| Use |

Deburring, improving corrosion resistance

|

| Material of work |

Austenitic stainless steel

|

| Size of work |

Palm size

|

| Chemicals mainly used |

Phosphoric acid electrolyte

|

| Current value |

~300A

|

| Main equipment |

|

| Main functions |

|

| option |

|

Features of NSC group companies’ electropolishing process

Among NSC group companies, special rectifiers are used to remove reaction products formed on an anode (metal smut) during electropolishing process.

With this method, detergency after electropolishing process is improved.

NSC’s 2 ways of design & fabrication for electropolishing machine

1.Design & fabrication according to procurement specifications

In the case where customers already have both fixed specifications for electropolishing machine and developed process technology, we design and fabricate the machine according to the “procurement specifications” instructed by customers.

2.Electropolishing process development and then the corresponding machine design

In the case where customers DO NOT have neither fixed specifications for electropolishing machine nor developed process techniques, our member company in Osaka will launch a process development starting from R&D. After customers’ evaluation on the trial pieces, the result will be reflected on the machine design.

Compared to the former case, in this case it takes both longer delivery time and higher cost, but on the other hand the machine may be delivered with process guarantee.

Results of electropolishing can be affected by various kinds of process factors. Main factors are listed up as follows:

1.Composition of the electrolyte

2.Temperature of the electrolyte

3.Process time

4.Shape and material of the electrodes

5.Distance between the electrodes and the workpiece

6.Current density

The key point is to find the most desirable process condition by combining these factors properly.

Sometimes the best process condition takes a long time to figure out; for combination patterns can be countless, so please contact us as soon as possible if you have needs.

NSC is able to offer designs without provided specifications

Customers do not have to worry even if there is neither fixed process condition nor determined specifications. In any case, feel free to contact NSC Engineering division if you need design & fabrication for experimental machines, machine prototypes, or mass production machines.

History of NSC group companies’ electropolishing business

NSC head office (Toyonaka City, Osaka Prefecture) has been taking contract orders for stainless surface treatment with electropolishing process as its main business.

By carefully assembling electrodes to each different workpiece which demands high quality in craftsmanship, as a result, our member company has been winning high evaluations in its expert techniques.

【Workpiece treatment record】

・For nuclear power plants: inner surface electropolishing of large-scaled piping

・For pharmaceutical factories: inner surface electropolishing of mixing tanks

・For semiconductor manufacturers: full surface electropolishing of vacuum chambers

With advantage of techniques cultivated in Japan, our overseas member company has been running contracting business in electropolishing process for various kinds of products from tanks for pharmaceutical factories to vacuum chambers for semiconductor manufacturers.

The whole NSC group companies came to making business innovation, and thereafter the above-mentioned electropolishing lines have ended their roles in NSC’s business field.

However, major machines which had been in operation were not disposed at all but instead, they were gathered to our member company located in Japan. These machines were applied to R&D uses so that our electropolishing technology was able to be passed to NSC Engineering division.

Currently, we are not engaged in the contract business of surface treatment in electropolishing, but we are responding to the design and fabricate of electropolishing machine for external sales.