Developing machine

Table of contents (Click to move to the lower part of this page)

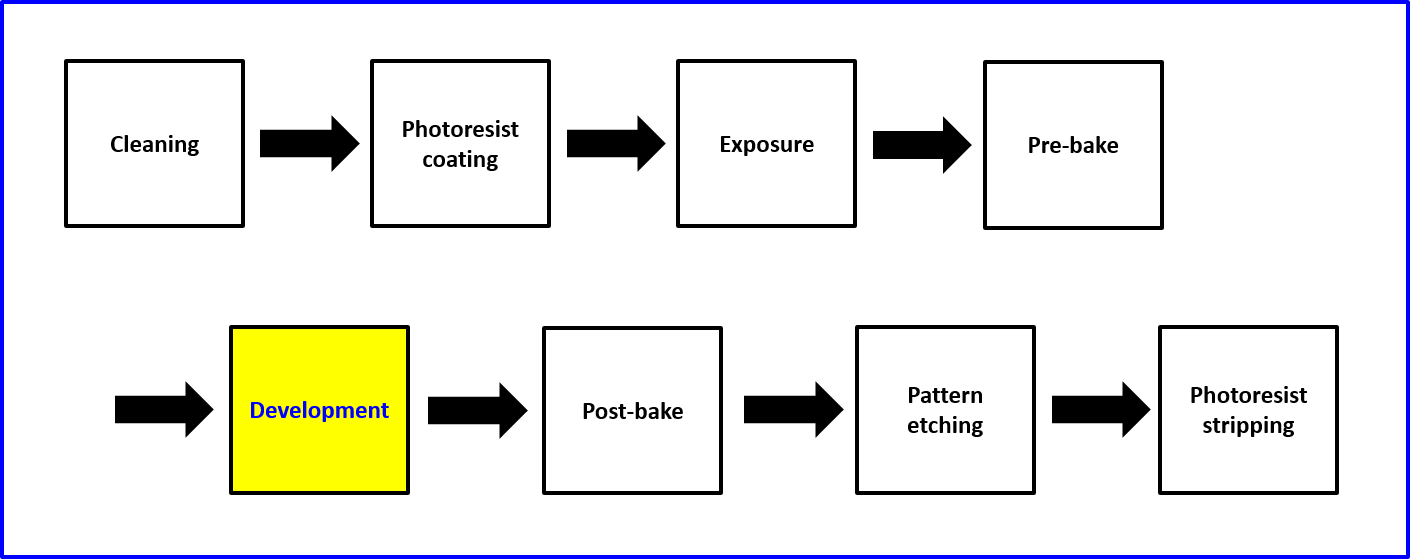

Development

Patterns are baked on substrates (printed substrates or glass substrates) coated with photoresist in exposure process, and in developing process, photoresist on the required parts of the patterns only will be left so as to protect these parts from etching in the next process; meanwhile, photoresist on the unnecessary parts of the patterns will be dissolved.

NSC has various kinds of fabrication records from developing machines in individual unit to in-line specifications integrated with post-bake equipment.

Developer solution

Alkali aqueous solution and organic solvent-based developing solution are mainly used, and sometimes it depends on the workpiece or photoresist.

Developing process

Developing process is mainly conducted as the following procedure.

The purpose of developing process is to dissolve the unnecessary photoresist while keeping the remaining photoresist on the required parts of pattern.

Sometimes in order to perform development smoothly, pre-bake process, in which water or organic solvent components are driven off the photoresist, is conducted after exposure process and before developing process.

After development, a small amount of water content or developer solution components may adhere on the workpieces. In some cases, in order to drive off the water content and developer solution components, post-bake process will be conducted before etching process.

For smooth workpiece delivery between the preceding process and later process, at NSC, specification design for loader/ unloader system are also provided in accordance with customers’ requirement.

Chemical supply system

It is essential to stabilize the developer solution during developing process. Development quality can be stabilized as long as the developer’s concentration, temperature, and supplement are kept in the best condition.

When designing the developing machine, NSC also provides chemical supply system if the situation requires.

Standing-position conveyance developing machine

Features

This machine has raising mechanisms which raise the workpieces lain flat on the machine to a standing position by an angle around 80 degrees.

The workpieces are conveyed in this standing position during developing process.

Developing, cleaning, and drying are performed coherently as a whole process.

NSC provides the suitable design according to the size of workpiece and chemicals to use.

Specification examples in our machine supply records

|

Item

|

Fabrication record

|

|---|---|

| Material of work |

Glass

|

| Thickness of work |

1.8~2.8mm

|

| Size of work |

L=2333mm、W=1663mm

|

| Chemicals mainly used |

Alkaline developer solution

|

| Takt time |

Approx. 75 secs.

|

| Standard delivery time |

4 months

|

| Safety measure |

Interlocks at each spot

|

| Operation system |

Automatic operation

|

| Control system |

PLC control

|

| System standard |

JIS, Japanese Industrial Standard

|

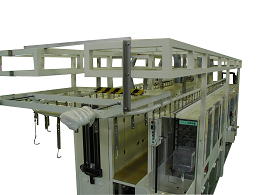

Horizontal conveyance developing machine

Features

This machine performs developing process while conveying the workpieces in horizontal direction.

Developing, cleaning, and drying are performed coherently as a whole process.

NSC provides the suitable design according to the size of workpiece and chemicals to use.

Specification examples in our machine supply records

|

Item

|

Fabrication record

|

|---|---|

| Material of work |

Glass

|

| Thickness of work |

1.8~2.8mm

|

| Size of work |

L=1700mm、W=2300mm

|

| Chemicals mainly used |

Alkaline developer solution

|

| Takt time |

Approx. 75 secs.

|

| Standard delivery time |

4 months

|

| Safety measure |

Interlocks at each spot

|

| Operation system |

Automatic operation

|

| Control system |

PLC control

|

| System standard |

JIS, Japanese Industrial Standard

|

Immersion-type developing machine

Features

This machine performs developing process through immersion.

Along with our chemical supply system, developer solution can be supplemented stably.

NSC provides the suitable design according to the size of workpiece and chemicals to use.

Specification examples in our machine supply records

|

Item

|

Fabrication record

|

|---|---|

| Material of work |

Glass

|

| Thickness of work |

5.0mm

|

| Size of work |

32 inches × 28 inches

|

| Chemicals mainly used |

Alkaline developer solution

|

| Standard delivery time |

3 months

|

| Safety measure |

Interlocks at each spot

|

| Operation system |

Semi-automatic operation

|

| Control system |

PLC control

|

| System standard |

JIS, Japanese Industrial Standard

|

Hanger-type developing machine

Features

It is a device that hangs the product on a hanger and performs continuous automatic development processing.

Developing, cleaning, and drying are performed coherently as a whole process.

NSC provides the suitable design according to the size of workpiece and chemicals to use.

Specification examples in our machine supply records

|

Item

|

Fabrication record

|

|---|---|

| Material of work |

Metals

|

| Thickness of work |

Depending on process conditions

|

| Size of work |

350×600mm

|

| Chemicals mainly used |

Alkaline developer solution

|

| Standard delivery time |

4 months

|

| Safety measure |

Interlocks at each spot

|

| Operation system |

Semi-automatic operation

|

| Control system |

PLC control

|

| System standard |

JIS, Japanese Industrial Standard

|

Manual developing machine

Features

Operation of NSC’s manual developing machine can be manual or semi-automatic.

This machine processes one workpiece at a time, which matches the needs of small-quantity production and trial production.

Specification examples in our machine supply records

|

Item

|

Fabrication record

|

|---|---|

| Material of work |

Glass

|

| Thickness of work |

5.0mm

|

| Size of work |

32 inches × 28 inches

|

| Chemicals mainly used |

Alkaline developer solution

|

| Process capacity |

1 sheet/ process

|

| Standard delivery time |

1 month

|

| Safety measure |

Interlocks at each spot

|

| Operation system |

Semi-automatic operation

|

| Control system |

PLC control, relay control

|

| System standard |

JIS, Japanese Industrial Standard

|

Additional examples from our machine supply records

NSC provides machine design & fabrication in accordance with customers’ various scenes.

|

Item

|

Fabrication record

|

|---|---|

| Material of work |

Stainless steel, 42 alloy, DFR, PET, glass

|

| Developer solution |

TMAH, sodium carbonate, and others

|