Chemical dimple suppression machine for glass products

To achieve process of slimming LCD glass substrates, there are 2 representative methods: “mechanical grinding” and “chemical etching”.

In recent days, chemical etching has been the mainly adopted method for its superiority in processing each glass substrate with a short takt time.

Among several different methods to perform chemical etching, in order to handle those LCD glass substrates growing larger in size, NSC chooses to design & fabricate single substrate chemical etching machines on which the glass substrates are conveyed in a horizontal lying position.

Machine types NSC designs & fabricates

|

Generation

|

Size (mm)

|

Sheet number/ Loading

|

|---|---|---|

|

Generation 8.5 (NSC is able to fabricate machines for G8.5 glass production) |

2200 x 2500

|

1 sheet/ Loading substrates loaded continually

|

|

Generation 6 (NSC has records in fabricating machines for mass production) |

1500 x 1850

|

1 sheet/ Loading substrates loaded continually

|

|

Generation 4.5 (NSC has records in fabricating machines for mass production) |

730 x 920

|

2 sheets/ Loading substrates loaded continually

|

Machine fabrication records

|

Item

|

Fabrication record (Generation 6)

|

|---|---|

| Material of work |

Glass

|

| Thickness of work |

Original thickness:1.0mm, 0.8mm, 0.5mm

|

| Chemicals mainly used |

Hydrofluoric acid etchant for dimple suppression

|

| Process capacity |

40,000sheet/month

|

| Takt time |

Approx. 50 secs.

|

| Standard delivery time |

5 months

|

| Safety measure |

Interlocks at each spot

|

| Operation system |

Automatic operation

|

| Control system |

PLC control

|

| System standard |

JIS, Japanese Industrial Standard

|

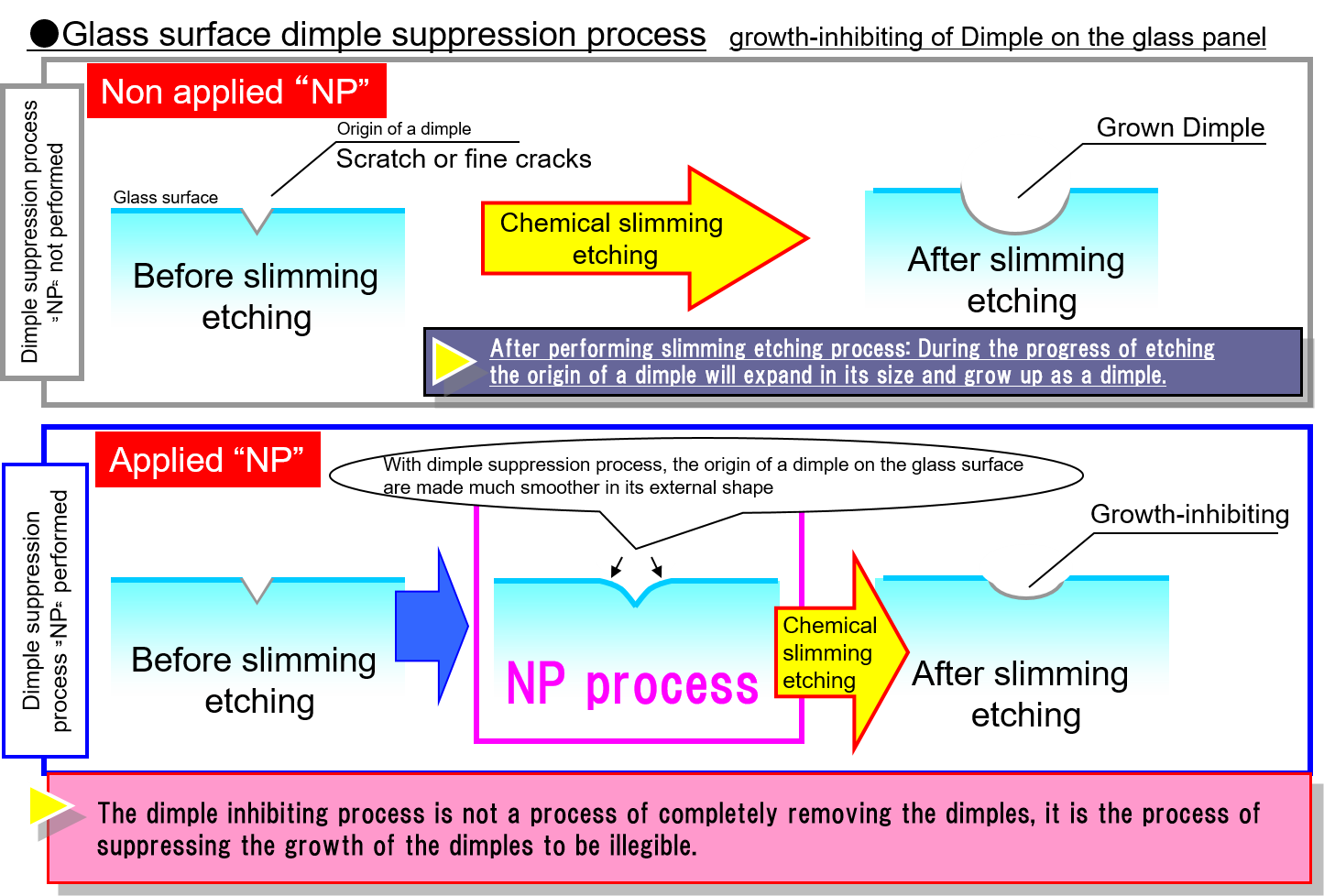

How dimples grow on glass surface & NSC’s original dimple suppression process

Any flaws or indentation cracks on the surface of a glass workpiece will expand and become dimples after chemical etching.

NSC’s original dimple suppression process, “NP Process,” is capable of suppressing growth of these dimples.

Glass dimple suppression treatment

Sometimes due to any of the below reasons mechanical polishing is required even after glass workpieces have reached the target thickness through chemical slimming process. These examples are sometimes also adopted as countermeasures to dimples.

1. Perform mechanical polishing on all workpieces whether or not there is any dimple defect

2. Perform mechanical polishing only on those workpieces with dimple defects (repair)

However, if mechanical polishing needs to be performed on all of the workpieces, in this situation the amount of processed workpiece is almost impossible to reach the required amount for mass production.

In addition, when mechanical polishing process is adopted as a means of repair, there may be a potential risk: If the ratio of dimple defects is high, production rate will be limited and such production rate may be too late to meet promised delivery time.

Considering the above-mentioned problems, NSC’s dimple suppression machine for glass products, “NP”, is the suitable machine which contributes to production efficiency among glass slimming lines.