Chemical etching machine for glass products

To achieve mass production of slimming LCD glass substrates, there are 2 representative methods: “mechanical grinding” and “chemical etching”.

In recent days, chemical etching has been the mainly adopted method for its superiority in processing each glass substrate with a short takt time.

Among several different methods to perform chemical etching, in order to handle those LCD glass substrates growing larger in size, NSC chooses to design & fabricate single substrate chemical etching machines on which the glass substrates are conveyed in a horizontal lying position.

Machine types NSC designs & fabricates

|

Generation

|

Size (mm)

|

Sheet number/ Loading

|

|---|---|---|

| Generation 8.5 (NSC is able to fabricate machines for G8.5 glass production) |

2200 x 2500

|

1 sheet/ Loading substrates loaded continually

|

| Generation 6 (NSC has records in fabricating machines for mass production) |

1500 x 1850

|

1 sheet/ Loading substrates loaded continually

|

| Generation 4.5 (NSC has records in fabricating machines for mass production) |

730 x 920

|

2 sheets/ Loading substrates loaded continually

|

Machine fabrication records

|

Item

|

Fabrication record (Generation 6)

|

|---|---|

| Material of work |

Glass

|

| Thickness of work |

1.0 → 0.20 mm (Ultra-thin, to a thickness of 0.05 mm)

|

| Chemicals mainly used |

Hydrofluoric acid slimming etchant

|

| Process capacity |

13,300 sheets/ month

|

| Takt time |

Approx. 125 secs

|

| Standard delivery time |

5 months

|

| Safety measure |

Interlocks at each spot

|

| Operation system |

Automatic operation

|

| Control system |

PLC control

|

| System standard |

JIS, Japanese Industrial Standard

|

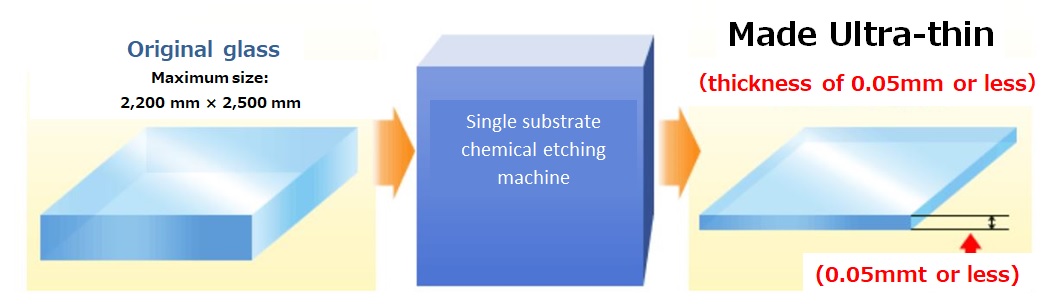

Features of ultra-thin glass slimming machine “NX”

The machine “NX” carries forward the glass substrates which are laid flat on the conveyor and at the same time sprays etchant (strong acid) onto these glass substrates. In this way, workpieces can be conveyed and slimmed simultaneously.

Total thickness of 0.05 mm or less can be realized after finishing the process.

Uses

|

Mobile devices which demand thinner and lighter glass substrates.

|

Example1. Smart phone |

The main point in fabricating an etching machine

For etching machines in general, given that strong acid is used as etchant, in most cases the machines should be made of plastic resin which is chemical resistant.

Resins can be processed by any equipment with high accuracy, however, resin welding techniques, which greatly affect the perfection of an etching machine, are not easy to be acquired.

To earn customers’ confidence in our machines, at NSC, only experts with techniques acquired through long experience, who are capable of excellent craftsmanship, will be in charge of our machine fabrication.