Anti-Glare(AG) processing machine for glass products

AG (Anti-Glare) Process

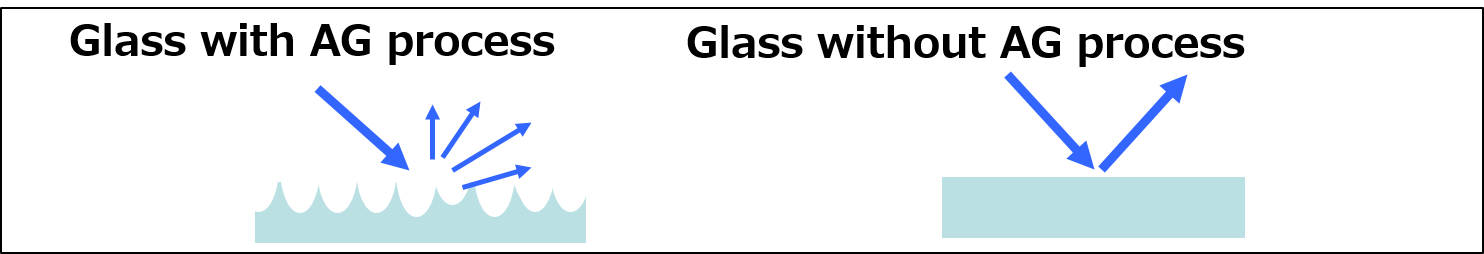

By creating rough texture onto the surface of glass, which make incident light reflect diffusely, glare from the glass surface (regular reflection) can be reduced.

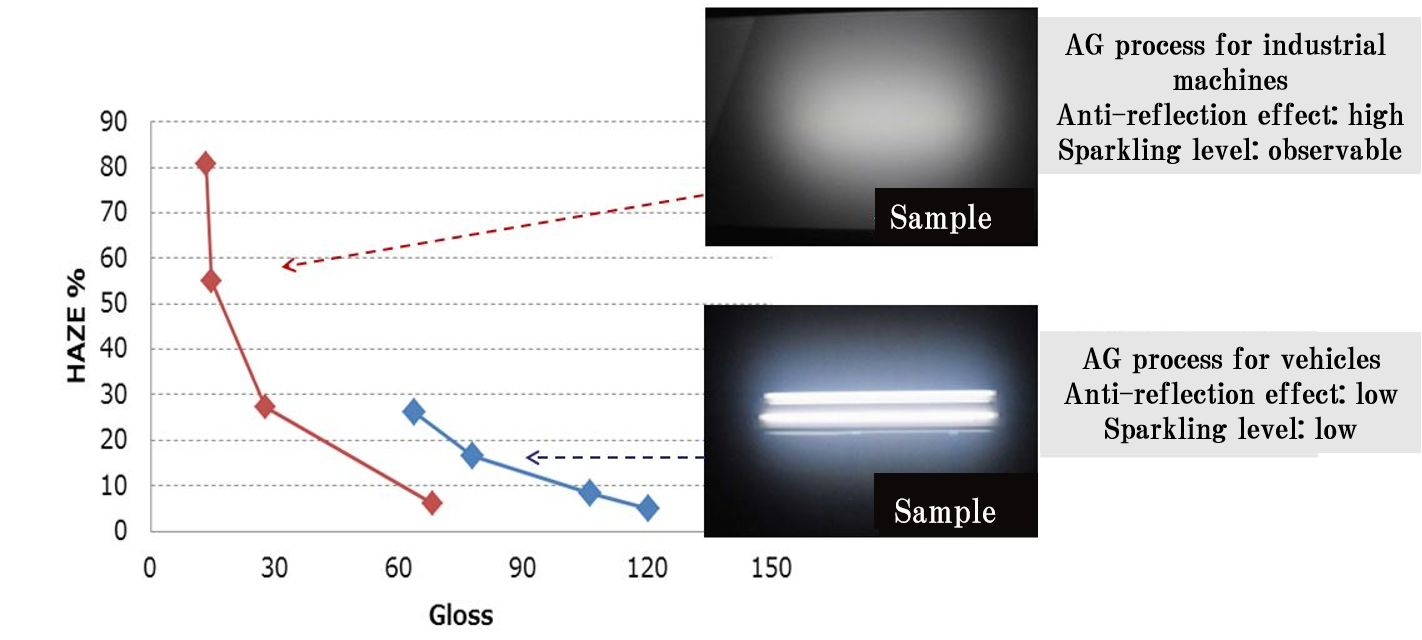

Reflection haze measurement for glass surfaces

|

By creating rough texture onto the surface of glass, which make incident light reflect diffusely, glare from the glass surface (regular reflection) can be reduced. *HAZE (%) = Diffuse transmittance/ total light transmittance×100

|

|

Features of Chemical Anti-Glare(AG) processing machine

NSC’s AG process involves applying a chemical-based surface treatment (chemical AG process) directly to the surface of glass to form micro asperities and gives the glass an anti-glare effect under the likes of sunlight.

-

01.Durability

NSC’s AG process is directly applied to the surface of glass to produce a product with high durability relative to general methods such as coatings and films.

-

02.Surface Strength

A feature of the chemical AG process is that it does not generate any of the minute flaws (micro-cracks) that are characteristic of mechanical AG processes and therefore maintains the high surface strength of the glass.

-

03.Applicable to High-Definition Displays

The AG process suppresses sparkling light, which makes it ideal for fabricating the cover glass of high-definition displays.

04.Haze rate control

|

Haze rate can be controlled by regulating chemical usage amount during the process. |

Optical property comparison in Haze & Gloss

|

Uses

|

Glass productions for vehicles that demand reduction in level of sparkling caused by interference between display and AG glass |

Example of use1. Cover glass for displays (for vehicles and industrial machines) |

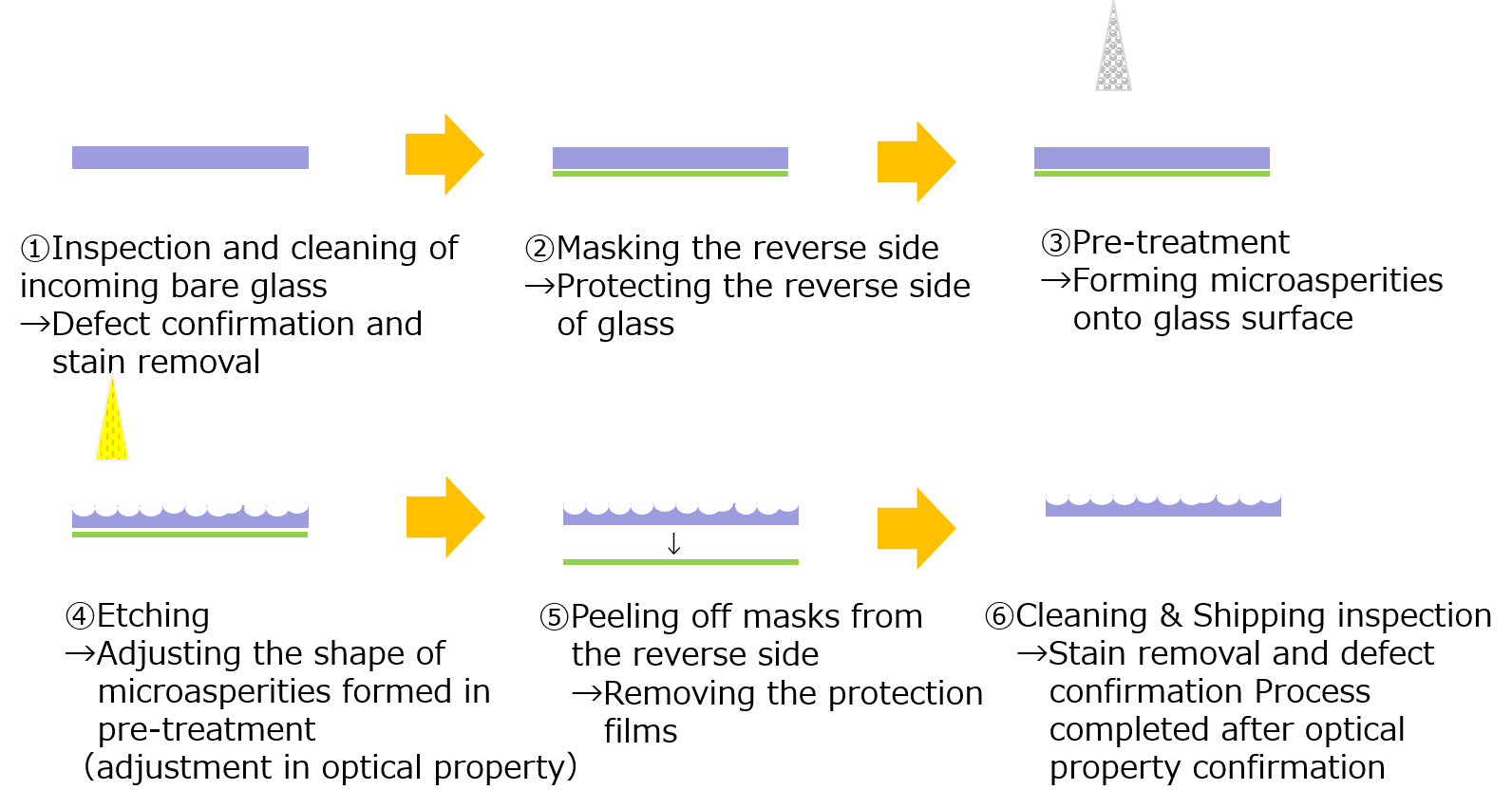

Process flow of NSC’s AG processing machine

Specification examples in our machine fabrication records

|

Item

|

Record

|

|---|---|

| Glass type |

Glass other than tempered glass

|

| Thickness |

0.3㎜~8㎜t

|

| Glass size |

100×100㎜~730×920㎜

|

| Chemicals mainly used |

Hydrofluoric acid etchant

|

| Process capacity |

Approx. 9,100 sheets/ months

|

| Takt time |

Approx. 240 secs.

|

| Standard delivery time |

5 months

|

| Safety measure |

Interlocks equipped

|

| Operation system |

Semi-automatic operation

|

| Control system |

PLC control

|

| System standard |

JIS, Japanese Industrial Standard

|

Scope of machines to be prepared (by Customer/ NSC)

| Machine | Customer | NSC |

|---|---|---|

| Cleaning machine (Before/ After process) | possible | possible |

| Laminator machine | possible | possible |

| Pre-treatment machine | – | possible |

| Etching machine (AG-NX) | – | possible |

| Laminate peeling machine | possible | possible |