Photoresist stripping machine

Table of contents (Click to move to the lower part of this page)

Photoresist stripping machine

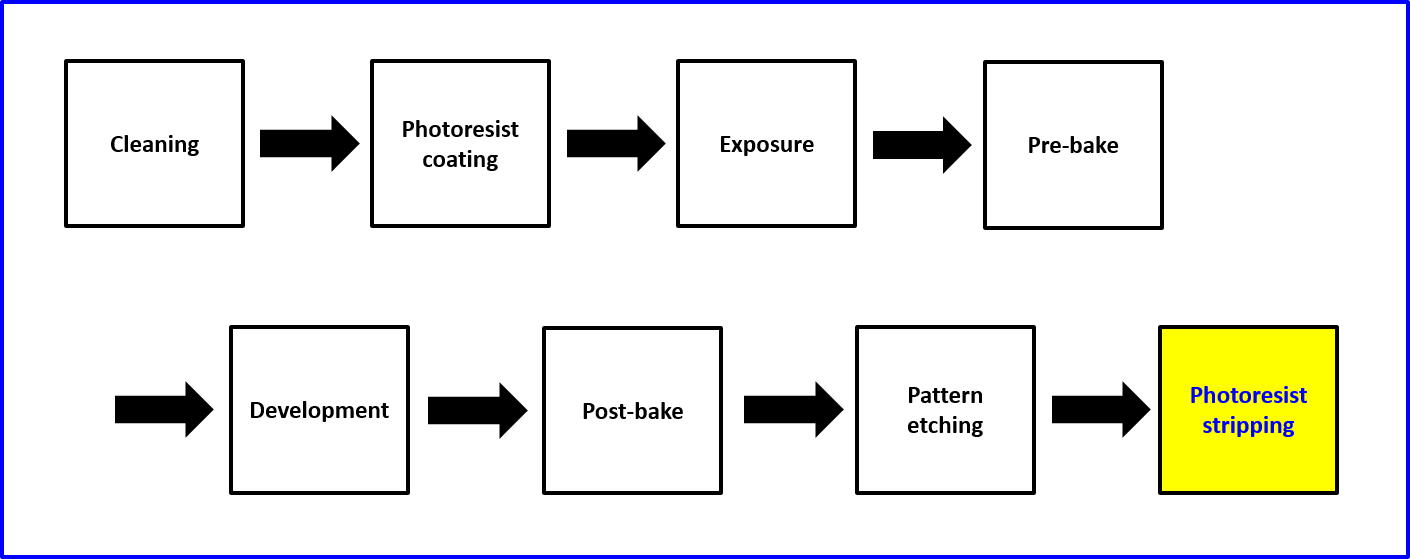

Photoresist stripping machines remove unnecessary resist materials after printed substrates/ semiconductor wafers are finished patterning etching. This process is called photoresist stripping.

One example of photolithography process

Photoresist stripping process can be conducted with two kinds of methods: “Dry process” uses plasma or ozone and “Wet process” uses alkaline aqueous solution or organic solvent such as organic amine (TMAH and the like) and ketone (acetone and the like).

NSC’s specialty is wet stripping process. From photoresist stripping machines to etching machines, we have fabrication records for integrated lines combining machines for the processes before and after photoresist stripping.

Following is one example from our machine supply records.

Individual process type stripping machine

Features

This machine strips off photoresist films in individual process type.

Consistently integrated procedure from stripping to cleaning and drying can be performed through automatic operation.

NSC provides the suitable design according to the size of workpiece and resist stripper solution.

Specification examples in our machine supply records

|

Item

|

Fabrication record

|

|---|---|

| Material of work |

Glass

|

| Thickness of work |

2.1mm

|

| Size of work |

460×460mm

|

| Chemicals mainly used |

Alkaline stripper solution

|

| Standard delivery time |

4 months

|

| Safety measure |

Interlocks at each spot

|

| Operation system |

Automatic operation

|

| Control system |

PLC control

|

| System standard |

JIS, Japanese Industrial Standard

|

Immersion-type stripping machine

Features

This machine stores small-sized workpieces such as chips to its cassette where photoresist films are removed through batch process.

A plural of workpieces can be processed all at once with various kinds of processing solution.

NSC provides the suitable design according to the size of workpiece and resist stripper solution.

Specification examples in our machine supply records

|

Item

|

Fabrication record

|

|---|---|

| Material of work |

Glass

|

| Thickness of work |

0.7mm

|

| Size of work |

Processing tank valid size 400 mm × 700 mm × H 300 mm

|

| Chemicals mainly used |

Alkaline aqueous solution, Organic alkaline stripper solution

|

| Standard delivery time |

2 months

|

| Safety measure |

Interlocks at each spot

|

| Operation system |

Manual operation

|

| Control system |

Relay control

|

| System standard |

JIS, Japanese Industrial Standard

|